Myotronics Test and Calibration Fixtures

Mandibular scanner model k7. One of several devices used in mandibular reconstruction.

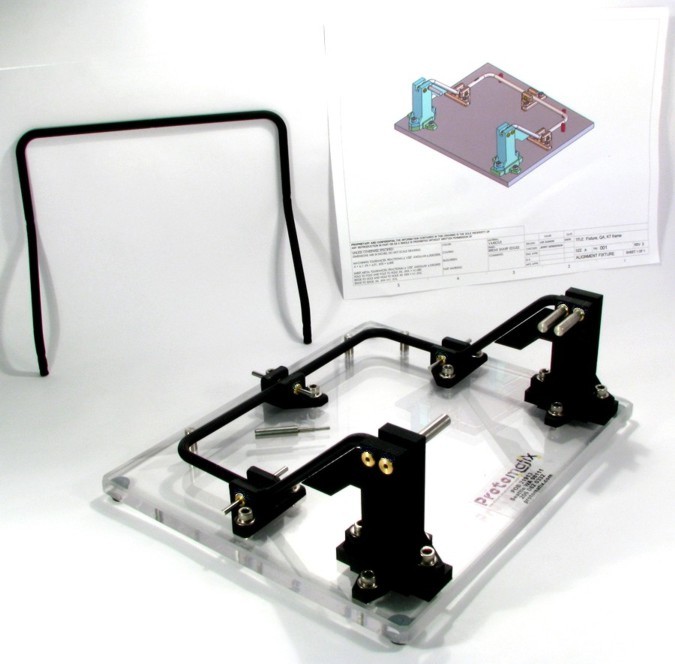

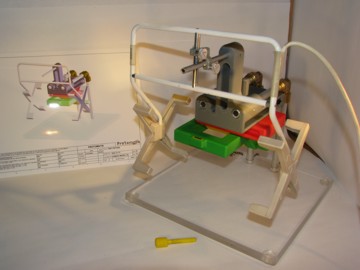

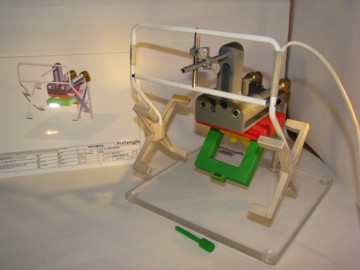

This inspection fixture checks for hole alignment and dimensions of a metal tubing part used in the assembly of the model K7.

FDM model of the tubing part (in background and on the inspection fixture).

FDM bushing holder parts (on fixture base) hold brass bushings that gage pins must slide through to inspect for a correctly fabricated tube part.

Note the high tolerance brass bushings pressed into FDM parts and four stepped steel gage pins (one center of fixture base, three in inspection position).

This type of fixture design reduced cost and delivery time to the manufacturing environment, compared to traditional all metal machined fixtures for many applications.

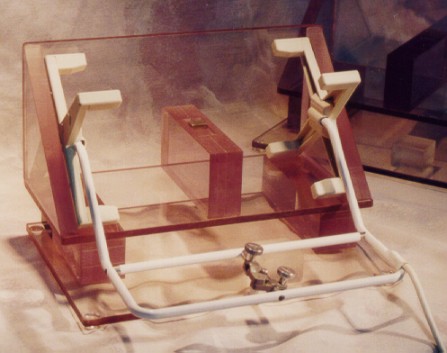

Mandibular scanner magnetic linear calibration fixture.

A characterized magnet must to pass a specific distance through the center of axis for calibration of UUT.

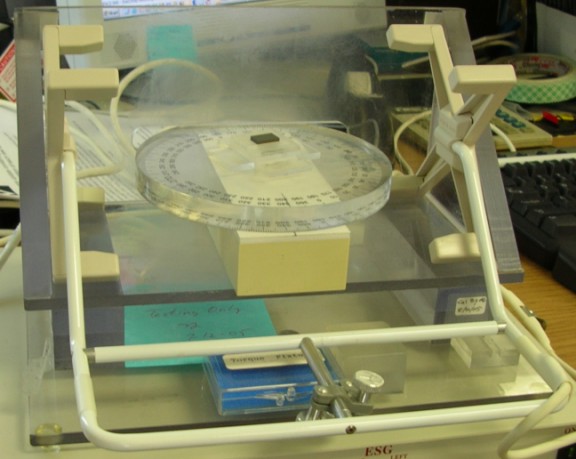

Mandibular scanner magnetic rotational calibration fixture.

A characterized magnet must rotate in the center of axis to a specific degree for calibration of UUT.

There were two linear fixtures made. One was converted to the rotational calibration fixture.

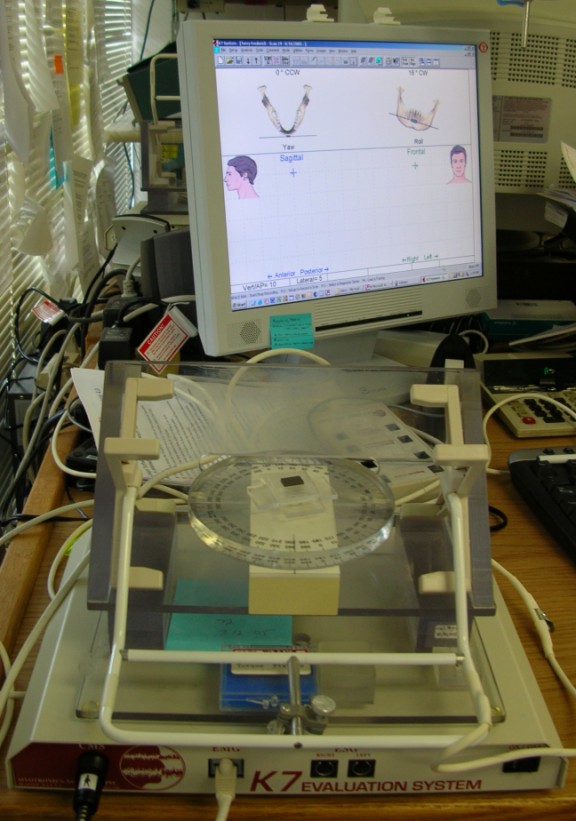

Software for test fixture on monitor.

Final test fixture to check UUT on XY and hinge Axis alignment.

The FDM process worked well in this application to create the dovetail movable pieces as ferrous metal in the area of the magnetic sensors would have distorted readings.

The CAD files for the dove tails were sized to account for FDM process interpolation and correct fit of the dove tails.

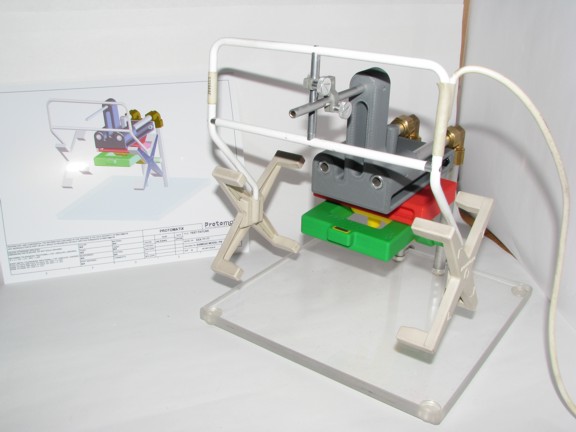

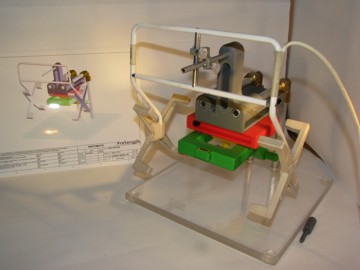

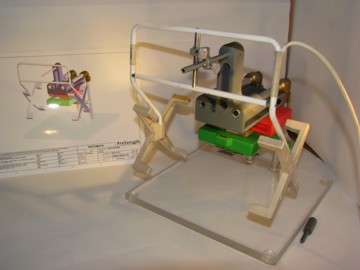

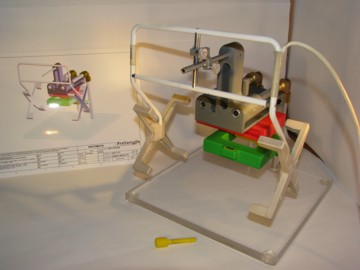

Pictures showing all axis of motion.

Before the dove tails for the fixture were created, a test was done on a scaled down version to check for fatigue.

The parts were actuated 10,000 cycle with no notable issues.

144Kb dovetail movie. Best viewed with Windows Media Player or a .wmv player.